Equipment

Home > Equipment

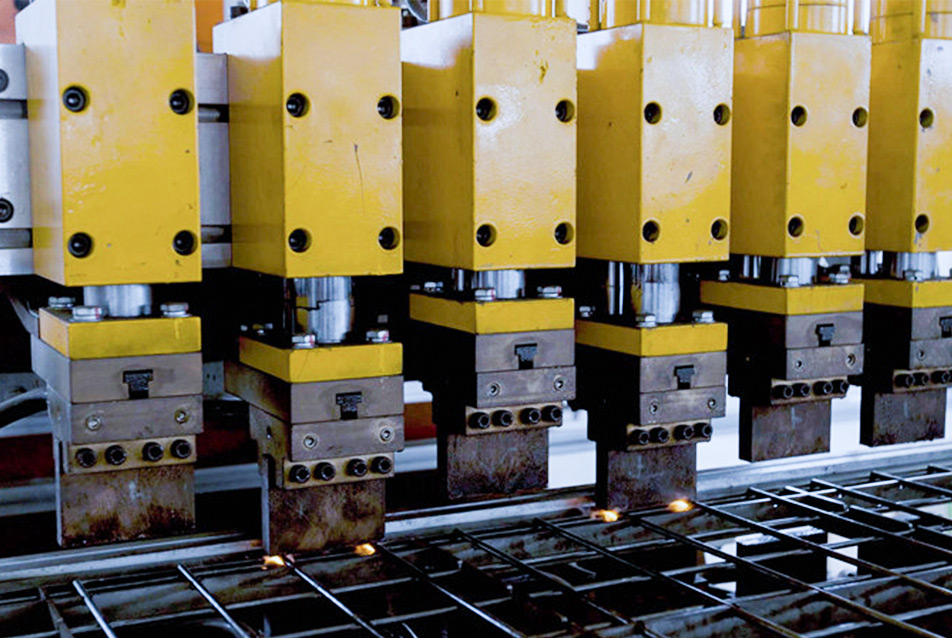

Spot Welding

Spot weld with a variety of products,wires,shelves,baskets...We have about 10 people in Spot welding shop.We strictly follow first article approval before mass production and process inspection against first article during production.All the goal is reducing defective products in production process.This is the way to controll lead time and make price efficiency.

Spot Welding Equipment and Technology

Except for basic spot machines,we have two multi-spot welding which is specialize for making big wire panels and shelves. Also we have a XY 2D machine is double efficient than multi-spot welding.What's our capability?

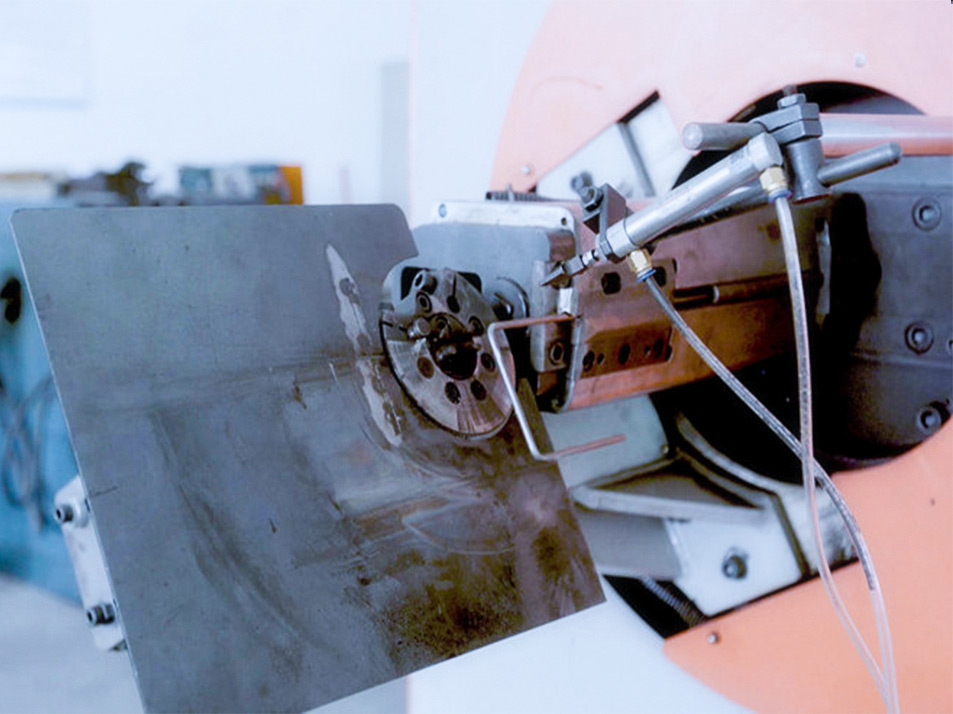

Spot and Bending Machines

Eight (8) wire bending tables

Three(3)4 corners hydraulic bending machine

Two(2)hydraulic wire decorating machines

One(1)automatic rounding machine

Two(2)automatic swedging machine

One(1)automatic tube rounding machine

Two(2)automatic tubes bending machine

One (1) digital sheet metal bending machine

One(1) heavy duty hydraulic sheet metal bending machine

Two(2)hydraulic sheet metal bending machine(165T)

Two(2) digital sheet metal bending machine

One(1) 3D Bender

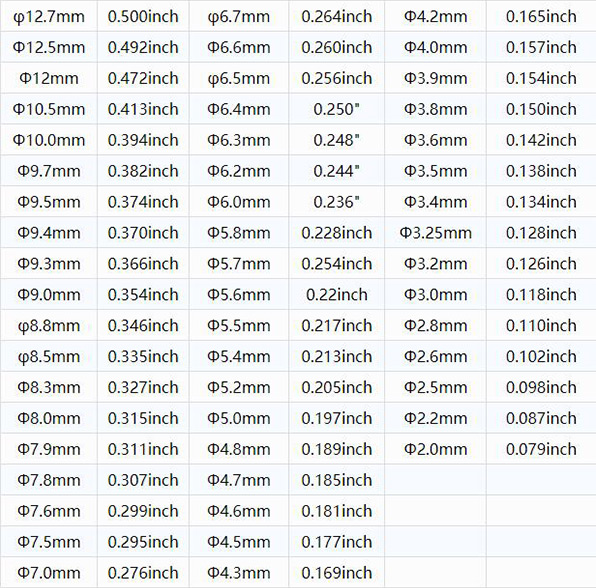

Wire-draw production line

Sintop buys raw material to draw the smaller gage wire for each production.the following thickness we can draw and normally use on our products.

Sintop buys raw material to draw the smaller gage wire for each production.the following thickness we can draw and normally use on our products.

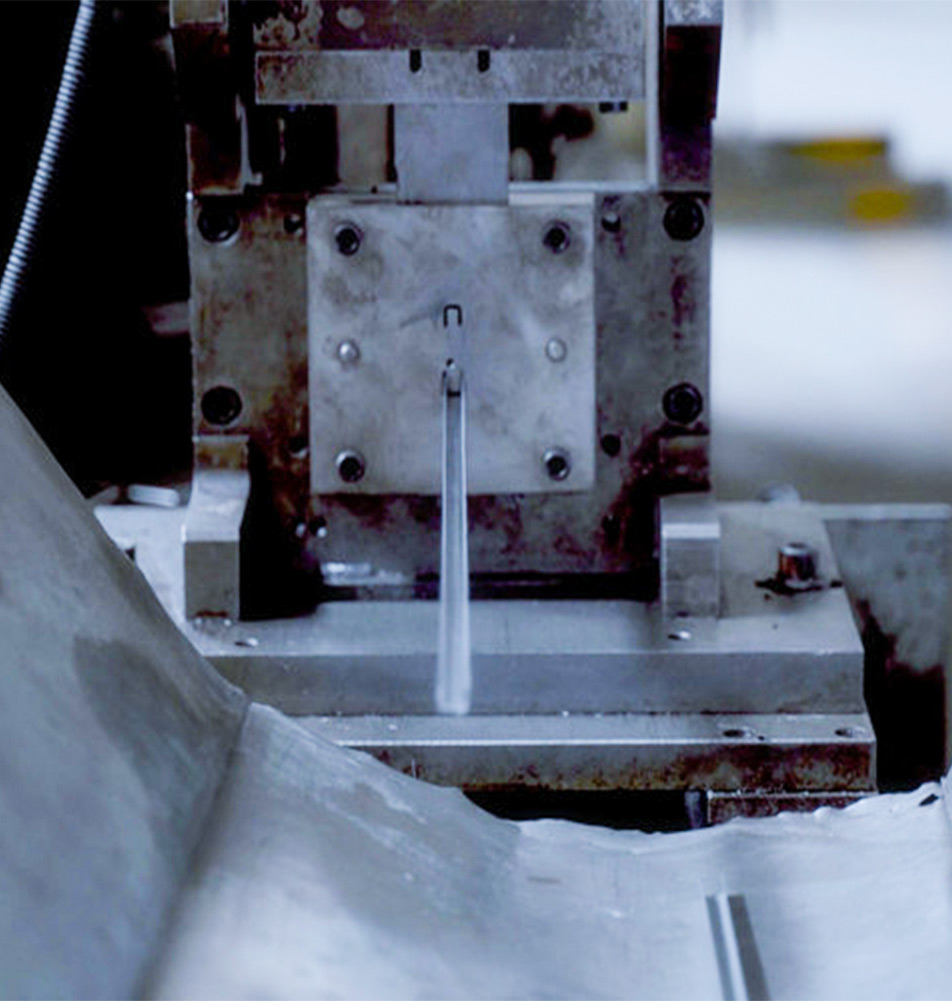

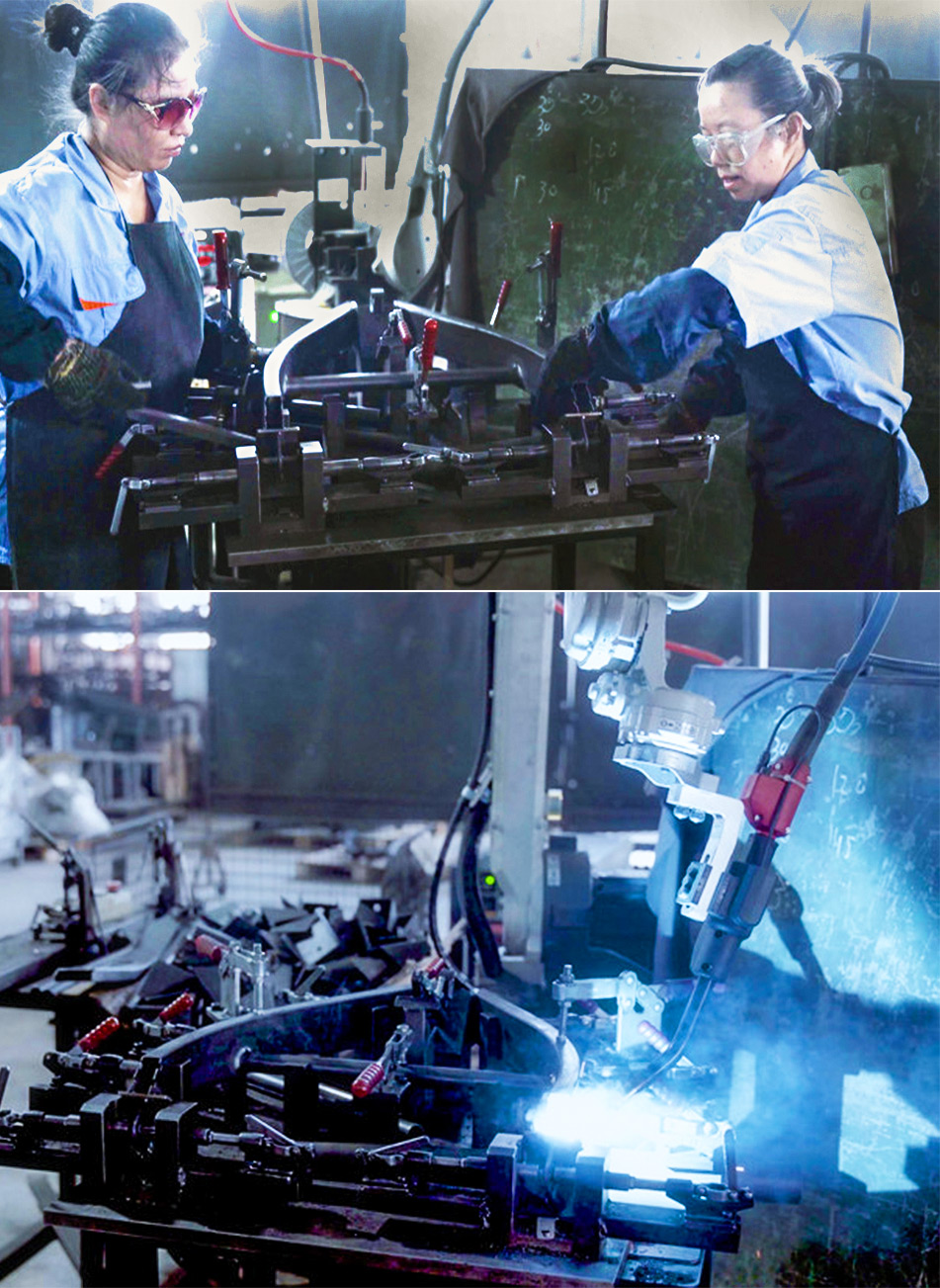

TIG/MIG Welding & Roboters

Weld Shop with a variety of welding Techniques and Capabilities Sintop welding shop employs over 30 welders. Although most hold professional welding certifications, Sintop ensures quality and precision by requiring every welder meet requirements laid out by our internal welding program. Our welders are experienced in a variety of welding techniques, including MIG and TIG Welding. Each welder has training with all metals used in our fabrication processes, including stainless steel, carbon steel and aluminum.

Welding Equipment and Technology

Not only are the Sintop welders trained to the highest standards, we've also invested in the latest technology that enhances our ability to produce precision parts at a rapid pace. Our eight robotic welding cells allow us to efficiently complete high-volume fabrication projects.Quality first article approval,employee self inspection and Q.C inspection frequently is done for every welding project, Sintop is often able to decrease production time, material cost, and labor cost for your project.

Robotic Welding

Eight (8) Panasonic robotic welding stations

MIG Welding

Seventeen (17) manual MIG welding stations

TIG Welding

Fifteen (15) manual TIG welding stations